Hastelloy C22 alloy is made of Nickel-Chromium-Molybdenum that has

high resistance to stress corrosion cracking, pitting and crevice corrosion. It

has resistance to the formation of grain boundary precipitates in the weld-heat

affected zone due to which it is suitable for use in the as-welded condition.

It has resistance to oxidizing and reducing media therefore it can be used in

upset conditions. It has excellent weldability and high corrosion resistance as

consumable filler wires & electrodes.

Hastelloy C22 Round Bars are used in various applications such as

·

Chemical Processing such as heat exchangers,

reactors and columns.

·

Waste Treatment

·

Pollution Control

·

Pulp and Paper Production

·

Marine Seawater

·

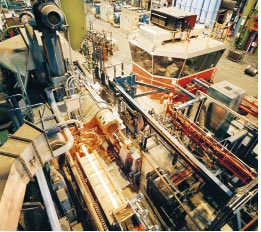

Petrochemical Plants

·

Oil & Gas Industry

·

Industrial Machinery

·

Refineries

·

Power Industry

·

Food Processing Industry

·

Chlorination Systems

·

Flue Gas Scrubbers

·

Pickling Systems

·

Acid Production

Hastelloy C22 is a wrought nickel-chromium-molybdenum alloy that

contains tungsten that further increases the corrosion resistance. It has high

resistance to localized corrosion, excellent metallurgical stability and is not

sensitized during welding or heating. It is available in various Bar forms such

as Square Bars, Hex Bars, Round Bars, Forged Bars, Polish Bars, Black Bars,

Bright Bars etc. Hastelloy C22 Alloy is ductile and is easily fabricated into

Industrial components.

Hastelloy C22 Alloy is amenable to the Gas Metal Arc, Shielded

Metal Arc and Gas Tungsten Arc welding processes. It is supplied in the Mill

Annealed condition as the solution annealing procedure is designed to optimize

the alloy’s corrosion resistance and ductility. This alloy should be

re-annealed after following all hot forming operations to restore excellent

properties. It should also be re-annealed after any cold forming operations

resulting in an outer fiber elongation of 7% or more. Hastelloy C22 alloy has

an annealing temperature of 1121°C and water quenching is recommended. Rapid

Air Cooling is suitable with structures thinner than 10 mm. A hold time at the

annealing temperature of 10 to 30 minutes is advised depending on the thickness

of the structure.

Hastelloy C22 alloy can be hot rolled, hot extruded, hot forged,

hot formed and hot upset. It is sensitive to strain and strain rates than the

austenitic stainless steels and the hot working temperature range is quite

narrow. The advised start temperature for hot forging is 1232°C and the advised

finish temperature is 954°C. Moderate reductions and frequent re-heating

provide the optimum results. This alloy can also be cold formed, drop hammered,

spinned, sheared and punched. It needs more energy for cold forming as it is

stiffer than austenitic Stainless Steels.

No comments:

Post a Comment